The line is dedicated mainly to exterior parts for KIA and Hyundai.

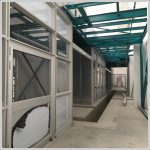

The painting process involves the application of three layers of paint into three spray booths in a row. In this first step, only one robot is located both in the base cabin and in the clear coat cabin: this is a convenient solution to meet the requirements of currently requested capacity and at the same time doesn’t break the budget of the project. However, the line was conceived in such a way that increasing performance in the future will be easily permitted by adding more robots into these cabins.

Air recirculation is implemented into the spray booths, so that it leads to optimization of the costs of preparing the air, especially in terms of air temperature and humidity.

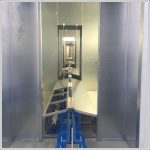

Only loading and unloading parts is carried out by the operators.

Whereas control and adjustment of the parameters of the working environment and the paint application is completely automated. This allows for ensuring the required paint manufacturer temperature and humidity inside spray booths and flash off.