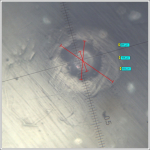

An indispensable stage of work when defining corrective actions is to identify what we will be dealing with, identify non-conformities.

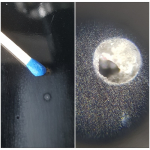

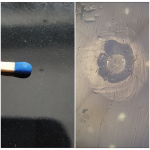

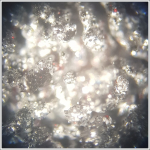

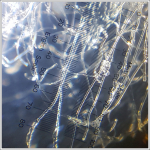

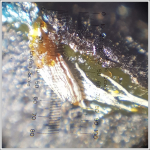

Let’s take a look at inclusions – the most common problem in painting process. If you want to reduce the number of non-conforming products due to inclusions, in the first step you should do is an analysis to understand what is behind the inclusion. The inclusion can be, for example, a varnish material or a fiber. There are different causes for each of these structures. Each of them requires different, specific actions.

Knowing what the problem is, you can choose the appropriate methods and tools to reduce or eliminate them.

Blindly defining actions may turn out to be ineffective – we will waste time, finance, we risk discouraging employees from taking up such challenges, and maybe even weaken the prestige of our company in the eyes of the client.

We offer an analysis of defects on the customer’s details / samples.

Prior arrangement, it is possible to collect samples from the customer or send samples to our company.

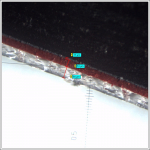

The analysis is completed with a report with photos and description of each defect as well as information about potential sources of the defect.